This screen is for industrial and wastewater with a capacity for large flows offering optimum solids separation by means of a mechanical system.

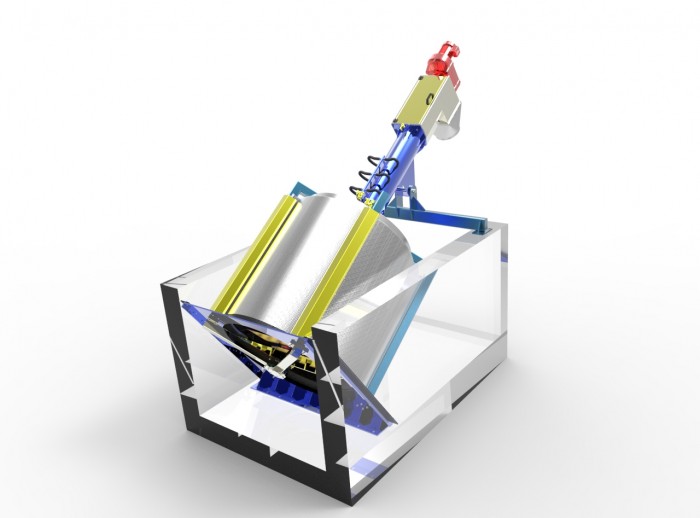

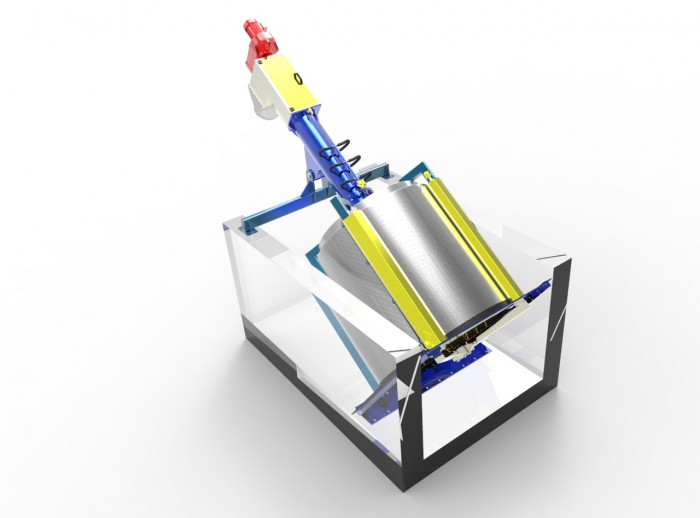

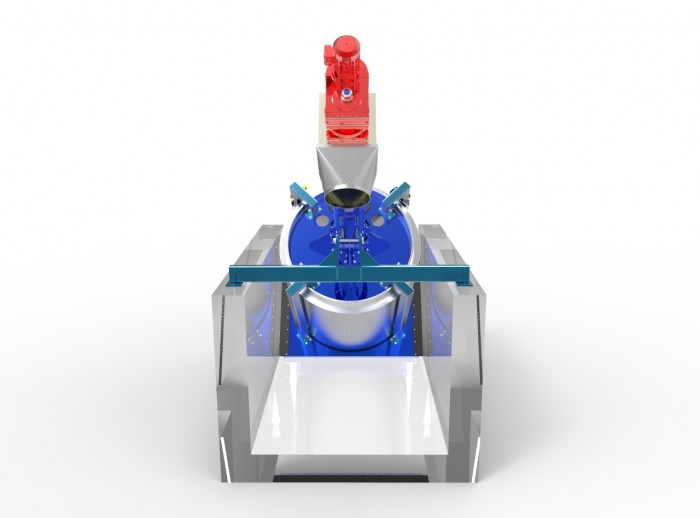

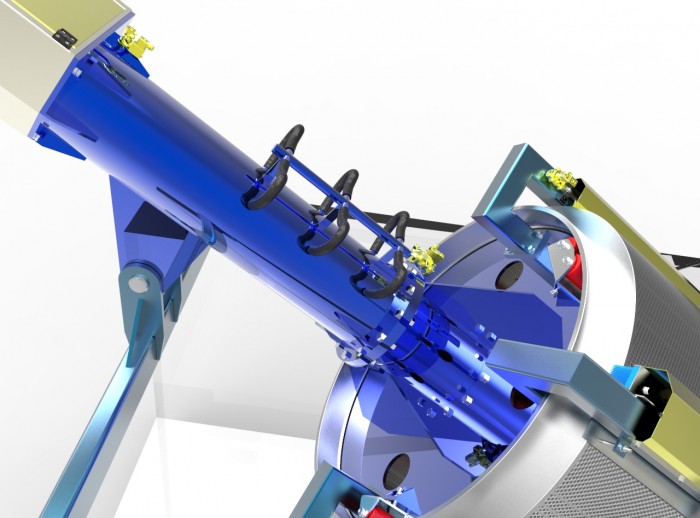

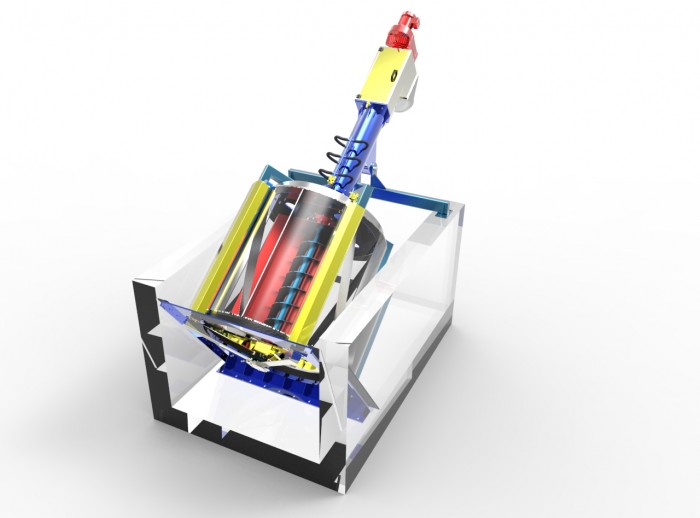

Compact design in metallic tank or in civil works.

Efficient cleaning system by friction.

Water injection cleaning systems in various zones is OPTIONAL.

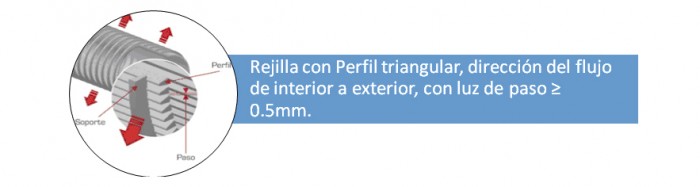

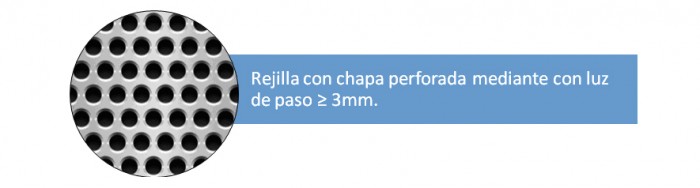

Different profile type in filtering (perforated or triangular profile).

No maintenance points (only visual inspection and periodical control).

DESIGN & APPLICATION:

Industrial or urban wastewater requires mechanical pre-treatment whereby suspended floating matter and solids are removed and our main issue which is the maximum separation of solids, is achieved, yet at the same time reducing the hydraulic head loss in the process. This way we can produce a higher output regarding all the posterior processes.

In order to achieve this, NETWATER has designed a series of machines known as: ArqTech®. We can offer different versions and dimensions according to the type of product to be treated and the required flow. All our equipment has different systems incorporated in order to offer the best results in screening, washing, compacting and transporting and where the solids are retained and extracted in just one piece of equipment.

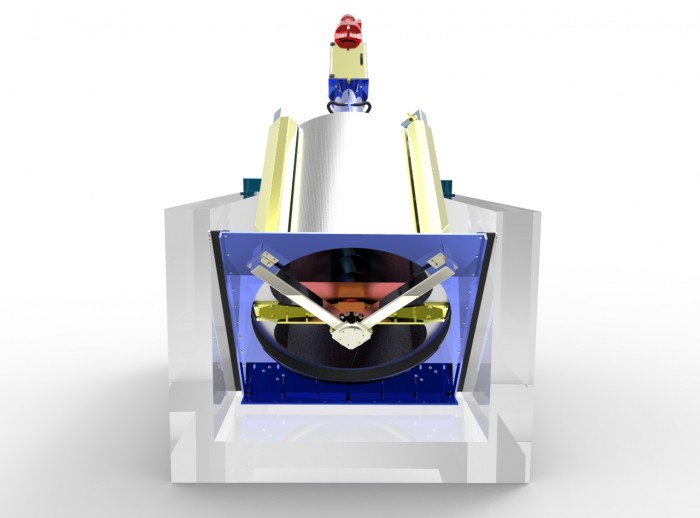

Our versatile design allows us to manufacture 2 types of filtering grid according to the type of solids and the flow to be treated.

OPTION A

OPTION B

In our wide range of products you can find the most adequate piece of machinery to suit your technical needs with basket diameters ranging from 800 to 2400mm.

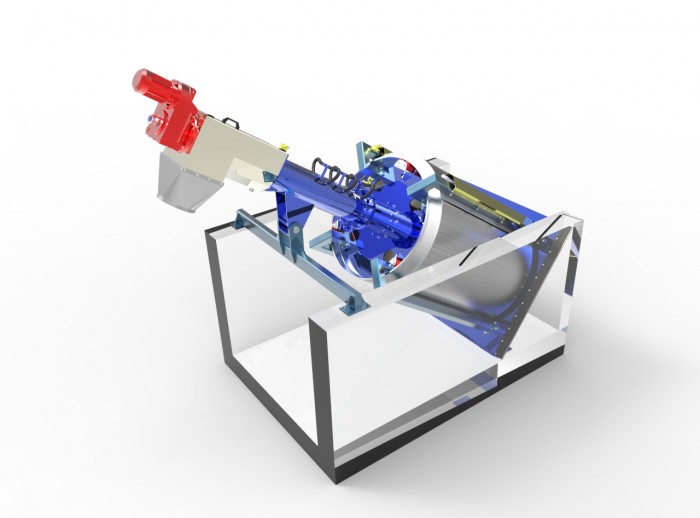

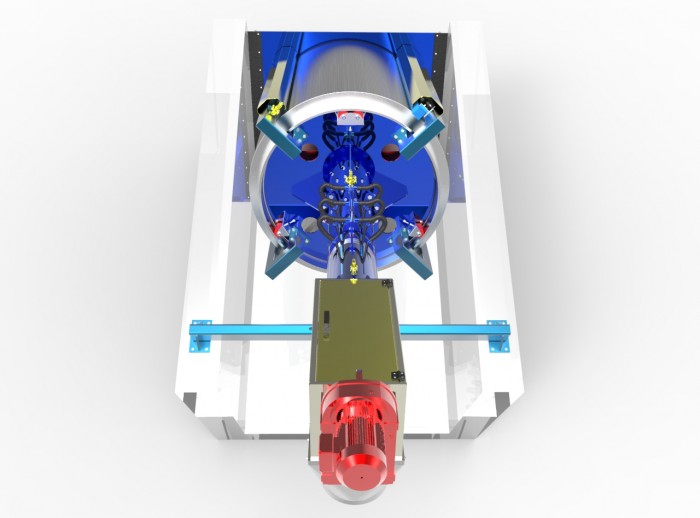

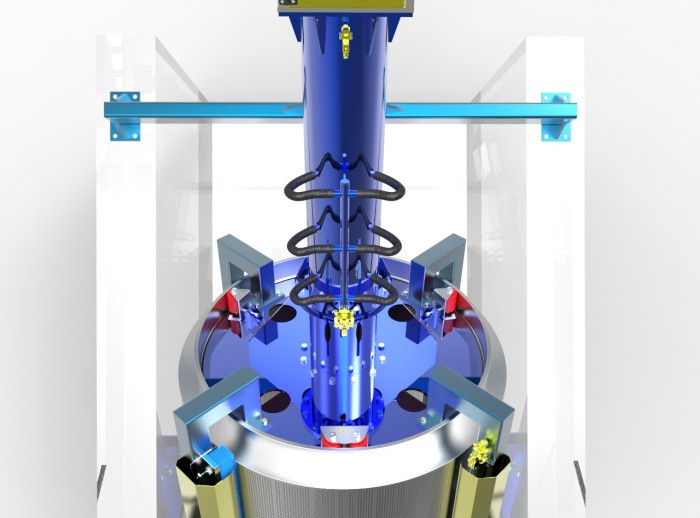

The equipment’s frame is manufactured in different qualities of Stainless Steel following the PREN Corrosion (Pitting Resistance Equivalent Number) and according to our client’s requests. Once manufacturing is concluded we apply a pickling process by means of an acid bath. The endless screw can be manufactured in Carbon Steel ST.52 (UNE F-1515) or in Stainless Steel, AISI-304/316.

4 processes are carried out with this equipment:

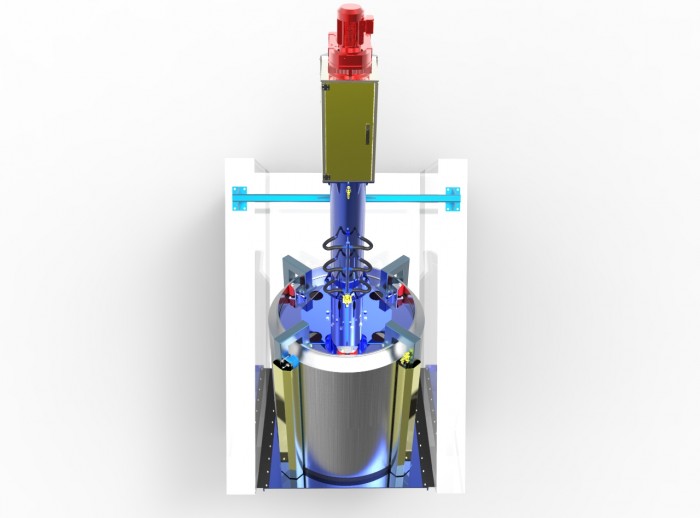

Process 1: The basket or the filtering grid retains and accumulates the solids on the filtering surface and this creates a difference in water levels. By means of a level control device (ultrasound sensors) this difference is detected and a signal is sent to the control panel which makes the basket turn clockwise. The basket has a system which raises the solids to the discharge zone and then from the highest point they start to fall due to gravity, into a collection hopper.

Process 2: The screw transports the solids which have fallen into the basket and at the part where the screw coincides with the waste collection hopper, we can install a cleaning system via friction whereby we are able to clean the perforated part of the hopper and this way we can drain excess water from the solids and from the basket’s cleaning system.

Process 3: Next the screw transports the solids through a closed tube made from stainless Steel and at this point we can offer OPTIONAL points of water injection in order to clean the solids and to avoid any blockages.

Process 4: The screw deposits the lifted solids into the compacting head where compacting takes place and this way we can reduce the volume and waste control expenses. The waste is deposited into a container or into a bagging system (which is OPTIONAL) and which can be installed at the equipment’s outlet.

The fine screen Arquímedes ArqTech®Nw55 has been designed to be installed directly into a civil works channel or in a compact metallic tank. As you can see in OPTION A, the flow circulates through the screen’s basket from inside to outside. The solids retention actually creates a positive effect increasing the equipment’s output as this layer of solids in itself, reduces the mesh size and retains solids which are smaller than the foreseen mesh and therefore there is a difference in water levels which is detected by a level control device (ultrasound) and hence all the systems begin to start (transporting, compacting and cleaning).

The main components are: filtering basket/ collection dumper / cleaning system by means of friction/ transporting tube / compacting head / endless screw / screw driving axis/ bagging system (optional) / cleaning systems.

For this equipment i’s necessary to install a soft-start device in the control panel due to the high torque required and this way we can protect all the components in the equipment, avoiding unnecessary breakages to any of the mechanisms which may be produced by tension on start-up.

Our equipment has a safety or protection system integrated in all the inspection lids, which is of utmost importance to be able to fulfil standards 2006/42/CE from European Parliament and the Consejo de 17 de mayo de 2006, relativa a las máquinas y por la que se modifica la Directiva 95/16/CE, establishes that all members of the European Union are obliged to adopt standards in order to ensure technical safety for the machinery

A safety element is OPTIONAL but we recommend our clients to incorporate this type of electronic device in the control panel and we can supply on demand. This way we can control various parameters and this device can be triggered off when abnormal activity is detected in the process and therefore we can avoid any further problems if the case of a blockage.